" We continue to satisfy our customers with expert

workmanship & competitive prices "

workmanship & competitive prices "

* Asphalt * Interlock * Concrete * Property Maintenance

* Line Painting * Crack Filling * Sealing * Snow Plowing

Pavement Specialist

(416) 885 - 7325

Interlock Stone

& Concrete

Powerwash & Seal

Contact us (416) 885-7325

& Concrete

Powerwash & Seal

Contact us (416) 885-7325

At TSP / Sealer People Inc. our goal is to make all Pavement, Interlock, Concrete & Wood Surfaces " look new again " for a fraction of the replacement cost.

Sealing interlock stone & concrete ensures that the surface is completely waterproof, resistant to stains & durable for lasting enjoyment.

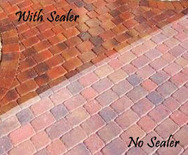

Some people believe that sealants only leave a shiny apprearance which is not always desired, however, there are sealants that can leave your surface looking natural with no wet look at all. (see picture above)

The final appearance or the finish after sealing is always determined by the home or property owner.

Before applying a sealant to any surface, a few detailed steps must be taken in order to ensure that the products work well & also last for the longest period of time possible. Our company guarantees that every step required will be completed properly & efficiently.

Step 1: Repair Sunken Areas

The surface should always be free of dips or depressions. It's always a good idea to have any sunken areas lifted & relayed to a proper grade & then compacted using a vibratory compactor or plate tamper to ensure that the stones are re-set & sit in place properly.

Step 2: Pressure Clean & Powerwash the surface of all dirt & debris.

This step will ensure that not only the stone surface is free of dirt, but by powerwashing the area any grass, weeds or moss growing between the joints will also be removed. This is a very messy process & the pressure washers being used must be of commercial grade in order to ensure that enough dirt between the stones gets cleaned out in order to allow for a generous application of polymeric sand.

Step 3: Applying Polymeric Sand

Polymeric sand is a great product to sweep between the joints of any stones driveway because of its strength, weed deterants & insect killing agents, however the product must be used properly in order for it to stabilize & set properly. Very often, many homeowners & contractors aswell who are not familiar with the product make simple mistakes which can lead to endless repairs & possibly replacement of the entire surface area.

This type of sand should never be installed less that one inch in thickness between the joints. When pressure washing is being done, the operator must ensure that he/ she removes enough dirt from between the joints to allow for the proper amount of polymeric sand to be installed. Not applying enough sand will result in flaking & peeling within the first few weeks.

Another important factor in the longevity of the sand, is that it gets watered before any sealants or treatments are installed. Applying water to sand, allows the polymers to activate & dry to a hard state in an even process. After the water has been misted on, a waiting period of 15 minutes should stand between the second watering. After this second misting of water, the sand should be well saturated & now be left to dry for 16 -24 hrs in order for the polymers to activate completely leaving the joint sand super hard & very well bonded to the stones.

Applying a polymeric sand properly dramatically reduces the risk of future grass, weed & vegetation growth between the stones. It also helps with the stability of the entire area in a whole. Polymeric sand gets so hard between the joints that it bonds the stones together which inturn allows the stones to act as an entire unit holding itself rather than just each stone individually.

The more area that is bonded together, the less likely the chance of settlement.

Step 4: Sealing the stones / Concrete/ Flagstone

Sealers comes in a variety of finishes such as : Matt (no shine), Semi Gloss, High Gloss & Super Shine or Premium Based.

They also come in water based or solvent based forms. Sealers can leave a surface with a wet looking appearance which is very popular or they can leave your surface looking dry. The type of finish used is a matter of preference.

Sealer will protect the surface from chemical spills such as gas, oil, antifreeze etc. Sealers also prevent the surface from getting damaged by salt in the winter months & also help with the surface remaining clean & free of dirt & traffic build up, haze from exhaust pipes & more.

Enhance your stone surface, enjoy the appearance & protect it at the same time. These are very costly products & without the proper care & maintenance could end up damaged, cracked, infested with weeds & vegetation growth that inturn can only be salvaged by having them completely removed & replaced.

Sealer People Inc. has been providing POWERWASH & SEAL SERVICES for well over a decade & we would be more than happy to discuss your next project with you.

Please contact us anytime for service: (416) 885 - 7325 or (416) 713 - 0613

Sealing interlock stone & concrete ensures that the surface is completely waterproof, resistant to stains & durable for lasting enjoyment.

Some people believe that sealants only leave a shiny apprearance which is not always desired, however, there are sealants that can leave your surface looking natural with no wet look at all. (see picture above)

The final appearance or the finish after sealing is always determined by the home or property owner.

Before applying a sealant to any surface, a few detailed steps must be taken in order to ensure that the products work well & also last for the longest period of time possible. Our company guarantees that every step required will be completed properly & efficiently.

Step 1: Repair Sunken Areas

The surface should always be free of dips or depressions. It's always a good idea to have any sunken areas lifted & relayed to a proper grade & then compacted using a vibratory compactor or plate tamper to ensure that the stones are re-set & sit in place properly.

Step 2: Pressure Clean & Powerwash the surface of all dirt & debris.

This step will ensure that not only the stone surface is free of dirt, but by powerwashing the area any grass, weeds or moss growing between the joints will also be removed. This is a very messy process & the pressure washers being used must be of commercial grade in order to ensure that enough dirt between the stones gets cleaned out in order to allow for a generous application of polymeric sand.

Step 3: Applying Polymeric Sand

Polymeric sand is a great product to sweep between the joints of any stones driveway because of its strength, weed deterants & insect killing agents, however the product must be used properly in order for it to stabilize & set properly. Very often, many homeowners & contractors aswell who are not familiar with the product make simple mistakes which can lead to endless repairs & possibly replacement of the entire surface area.

This type of sand should never be installed less that one inch in thickness between the joints. When pressure washing is being done, the operator must ensure that he/ she removes enough dirt from between the joints to allow for the proper amount of polymeric sand to be installed. Not applying enough sand will result in flaking & peeling within the first few weeks.

Another important factor in the longevity of the sand, is that it gets watered before any sealants or treatments are installed. Applying water to sand, allows the polymers to activate & dry to a hard state in an even process. After the water has been misted on, a waiting period of 15 minutes should stand between the second watering. After this second misting of water, the sand should be well saturated & now be left to dry for 16 -24 hrs in order for the polymers to activate completely leaving the joint sand super hard & very well bonded to the stones.

Applying a polymeric sand properly dramatically reduces the risk of future grass, weed & vegetation growth between the stones. It also helps with the stability of the entire area in a whole. Polymeric sand gets so hard between the joints that it bonds the stones together which inturn allows the stones to act as an entire unit holding itself rather than just each stone individually.

The more area that is bonded together, the less likely the chance of settlement.

Step 4: Sealing the stones / Concrete/ Flagstone

Sealers comes in a variety of finishes such as : Matt (no shine), Semi Gloss, High Gloss & Super Shine or Premium Based.

They also come in water based or solvent based forms. Sealers can leave a surface with a wet looking appearance which is very popular or they can leave your surface looking dry. The type of finish used is a matter of preference.

Sealer will protect the surface from chemical spills such as gas, oil, antifreeze etc. Sealers also prevent the surface from getting damaged by salt in the winter months & also help with the surface remaining clean & free of dirt & traffic build up, haze from exhaust pipes & more.

Enhance your stone surface, enjoy the appearance & protect it at the same time. These are very costly products & without the proper care & maintenance could end up damaged, cracked, infested with weeds & vegetation growth that inturn can only be salvaged by having them completely removed & replaced.

Sealer People Inc. has been providing POWERWASH & SEAL SERVICES for well over a decade & we would be more than happy to discuss your next project with you.

Please contact us anytime for service: (416) 885 - 7325 or (416) 713 - 0613

Polymeric Sand

Powerwash Dirt & Debris

Interlock & Concrete Sealing

Wet Look

Dry Look Seal